Pelanggan: Sebuah syarikat sewa di Malaysia

lokasi: Malaysia

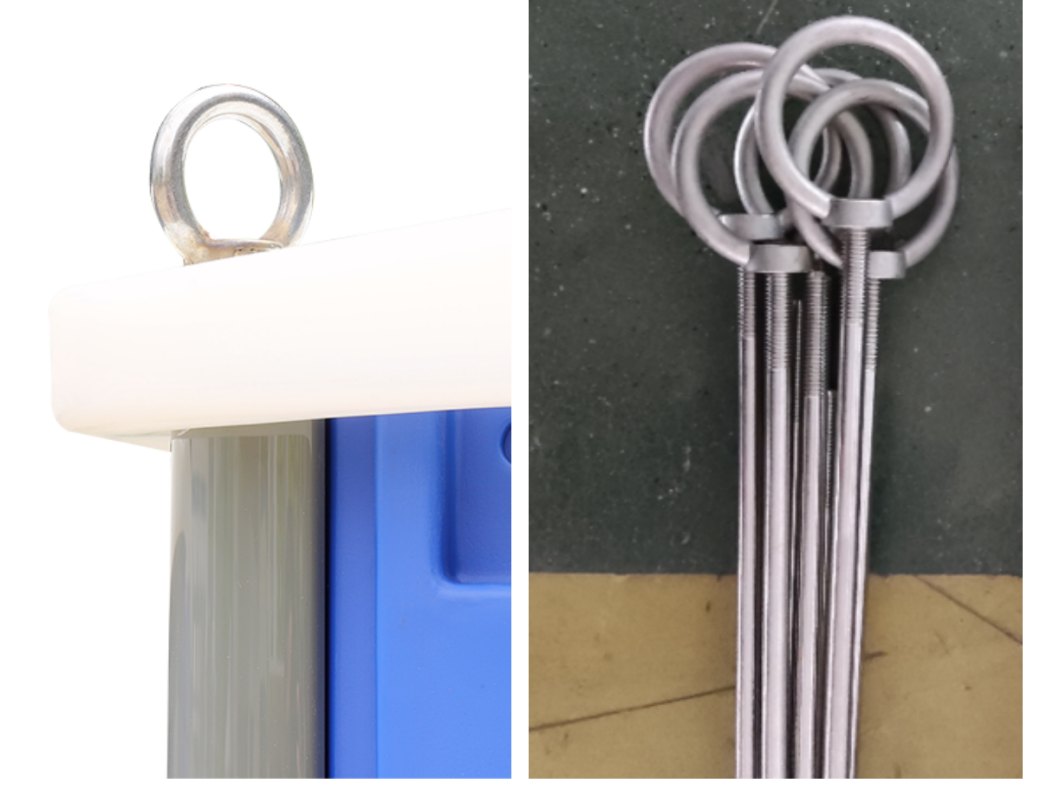

produk: Standard Tandas Mudah Alih dengan cincin Mengangkat

Ciri Utama Digunakan: Batang Pengangkat & Gelang Dipasang di Bumbung

Cabaran: Pelanggan memerlukan pemindahan unit tandas mudah alih yang kerap di pelbagai tapak projek di Malaysia menggunakan trak yang dilengkapi dengan lengan kren hidraulik. Tandas mudah alih tradisional selalunya kekurangan titik angkat yang berdedikasi dan teguh yang direka khusus untuk cangkuk kren, menjadikan proses pemuatan, pemunggahan dan penempatan semula menyusahkan, memakan masa dan berpotensi tidak selamat. Mereka memerlukan penyelesaian yang disepadukan dengan lancar dengan armada yang dilengkapi kren mereka untuk pengendalian yang pantas dan selamat.

Penyelesaian: Kami direka khas Standard Tandas Mudah Alih dengan Sistem Rod Pengangkat Bersepadu telah dikerahkan. Ciri reka bentuk utama yang memenuhi keperluan pelanggan secara langsung ialah:

Empat Batang Pengangkat Keluli Bertetulang: Empat batang keluli yang besar disepadukan secara menegak ke dalam struktur tandas.

Integrasi Bumbung ke Pangkalan: Joran ini berjalan secara berterusan dari bumbung ke bawah ke rangka asas daripada unit, memastikan daya diagihkan di sepanjang keseluruhan ketinggian struktur dan bukan hanya pada panel bumbung.

Cincin Angkat Tugas Berat: Gelang angkat yang teguh dan dikimpal dipasang dengan selamat pada hujung atas setiap batang keluli, menonjol dengan jelas di atas garisan bumbung. Cincin ini bersaiz sempurna untuk cangkuk kren standard.

Pengikat Pangkalan Selamat: Hujung bawah setiap batang keluli dilabuhkan dengan kukuh pada rangka tapak teguh tandas menggunakan tegangan tinggi yang besar. kacang pengunci. Ini mewujudkan struktur pengangkatan yang tegar dan penting yang diikat terus pada asas unit.

Kebolehcapaian Mesra Kren: Kedudukan gelang yang tinggi di atas bumbung menyediakan akses tanpa halangan untuk cangkuk kren.

Pelaksanaan & Keputusan di Malaysia:

Selepas penghantaran ke tapak pelanggan di Malaysia, unit telah bersedia untuk pengendalian kren segera.

Pelanggan menggunakan kumpulan trak sedia ada mereka yang dipasang dengan lengan kren hidraulik.

Pengendali kren mudah disambungkan pada empat gelang angkat yang boleh dilihat dengan jelas dan boleh diakses.

Sistem rod bersepadu memastikan daya angkat yang seimbang sempurna. Sambungan tegar dari gelang melalui rod turun ke nat asas berkunci memberikan kestabilan yang luar biasa semasa keseluruhan proses pengangkatan, menghapuskan kebimbangan goyah atau tekanan struktur.

Memuatkan ke atas trak pengangkutan dan pemunggahan seterusnya di tapak destinasi telah selesai dengan cepat, lancar dan selamat.

Pelanggan melaporkan penjimatan masa dan buruh yang ketara berbanding kaedah sebelumnya (cth, forklift, pengendalian manual, atau kaedah anduh yang kurang selamat). Proses itu digambarkan sebagai "sangat mudah" dan "tidak mudah."

Kekukuhan sistem rod angkat dan gelang, yang diikat dengan kacang asas, memberikan pelanggan keyakinan sepenuhnya terhadap keselamatan dan ketahanan unit semasa lif kren berulang, walaupun dalam keadaan operasi Malaysia yang mencabar.

Maklum Balas Pelanggan: "Gelang pengangkat bersepadu pada rod yang dibina betul-betul ke dalam struktur adalah penukar permainan untuk kami. Menggunakan trak kren kami, kami boleh mengambil dan mengalihkan tandas ini dalam beberapa minit. Reka bentuknya sangat kuat dan stabil – kami tidak perlu risau tentang merosakkan unit semasa mengangkatnya. Ia betul-betul penyelesaian pengendalian yang selamat dan mudah yang kami perlukan untuk operasi kami di seluruh Malaysia."